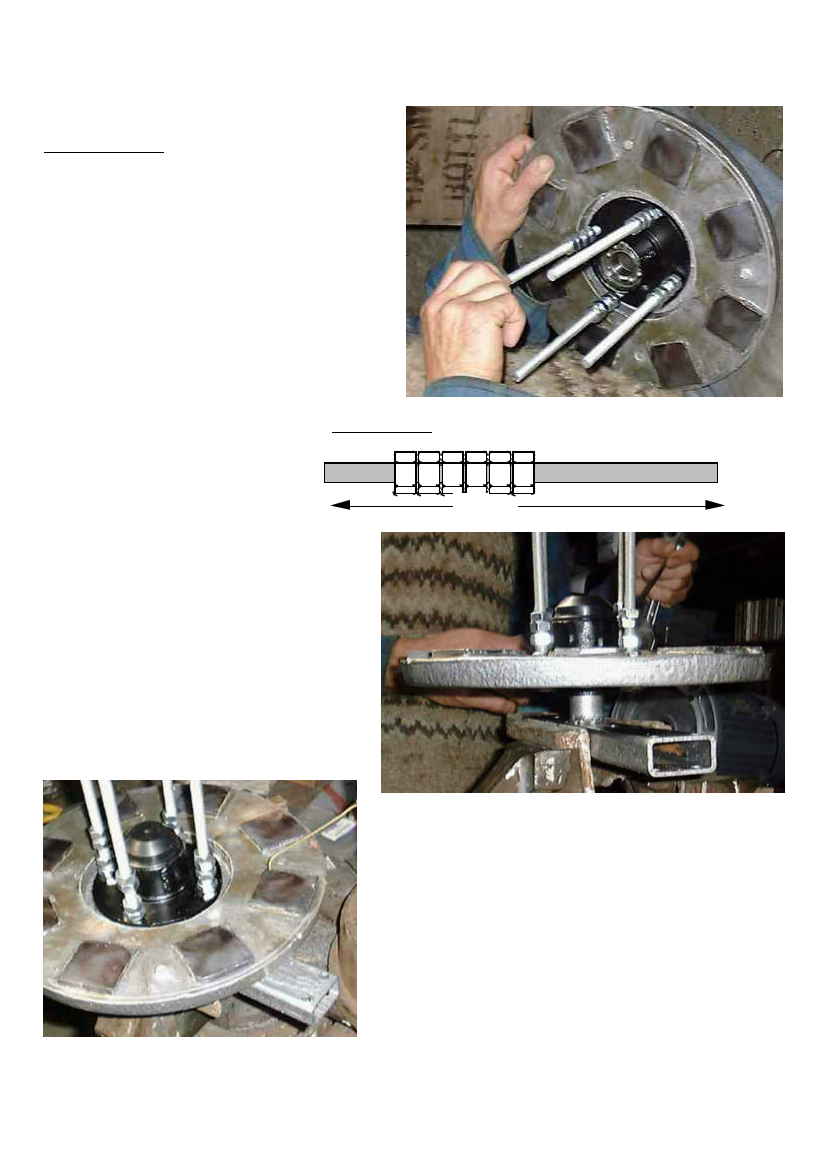

Photos show the rear magnet rotor being fitted

PMG assembly

• Cut 4 pieces of M10 threaded rod,

each 200 long. They are used as

studs to hold the magnet rotors to

the hub. The wind turbine blades

will also mount onto these studs.

• Put 6 nuts onto each stud) see

diagram 41).

• Fit the studs through the holes in the

bearing hub, from the front

• Put the rear magnet rotor onto the

ends of the studs.

• Put a nut on the end of

each stud, and tighten the

other nuts down, so that

41. STUDS

the rear magnet rotor is

attached to the back of

the hub flange. The outer

end nut should be sealed

with paint or thread-

sealant.

• Place the spine in a vice with the

shaft upward. Place the hub onto

the shaft. Do not hammer the

magnet rotor while fitting.

Fasten the hub to the shaft with a

nut and split pin. Do not over

tighten the nut. Fit a dust cover

over the end of the bearing hub.

THREADED ROD

200mm

10mm

PMG manual

• Rotate the magnet rotor past a piece of

brass wire. Do not use steel wire, because

it is attracted to the magnets. The magnet

faces should all be at the same height +/-

0.5mm. If not, use very thin shims between

hub-flange and rotor-disk, to adjust the

rotor.

• Using a spirit level, adjust the spine in the

vice until the magnet rotor is level. Check

both ways: north-south and east-west.

• Take the stator. Fit one 8 mm nut onto each

support stud. Screw them right down.

page 38

June 2001